After four years of physical, chemical and mechanical tests, eKKomaxx cement has now been given a Technical Appraisal (ASTM,ACI & LEED GREEN BUILDING ASSOCIATION). The appraisal covers a large number of structures ranging from detached houses to high-rise buildings in terms of their structural applications (floors, diaphragm walls, beams, posts, etc.).

These technical appraisals guarantee a lifespan of over 100 years for structures built with eKKomaxx cement.

NU GREEN “eKKomaxx” cement replaces Portland cement and is well-positioned to meet the challenges of sustainable development.

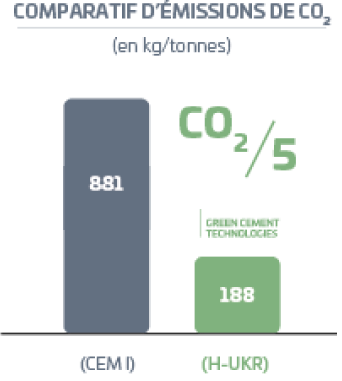

eKKomaxx and Great White Shark (GWS) cement contains 0% clinker and is made from industrial by-products and activators from the chemicals industry, using a cold process which produces low-carbon concretes.

Characteristics of eKKomaxx & GWS cement

eKKomaxx contains not a single gram of clinker. Its carbon footprint is a quarter of that of traditional cement and it has a compressive strength of up to 6000 PSI after 90 minutes and reaching more that 13000 PSI in 28 days.

eKKomaxx cement is supplied in powder form, can be stored in silos and is fully compatible with existing manufacturing processes. It is intended for the industrial concrete, precast and ready-to-use markets.